Manufacturing

An all-in-one solution that seamlessly integrates Manufacturing, Shop Floor, PLM, Quality, and Maintenance for a streamlined and intuitive user experience.

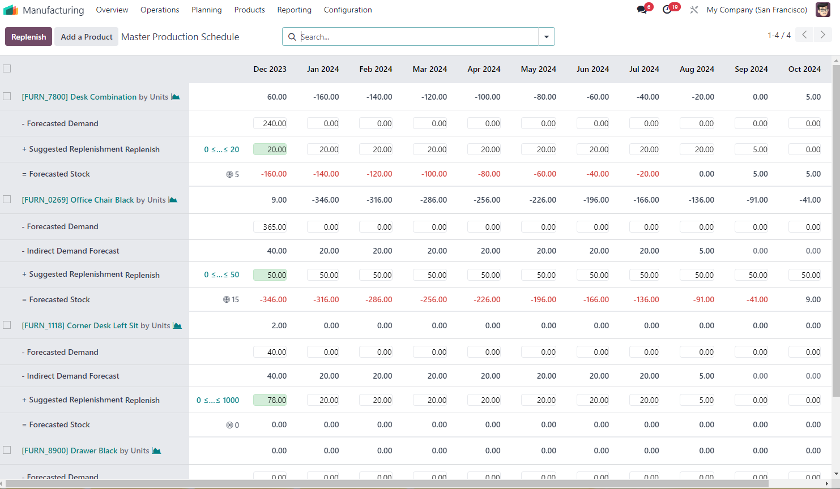

Master plan

Develop a comprehensive annual plan for all products on a daily basis, ensuring that the finished goods warehouse maintains the minimum quantities required for each product. Streamline the process by generating production orders and purchase orders for the necessary materials with just one click directly from the plan.

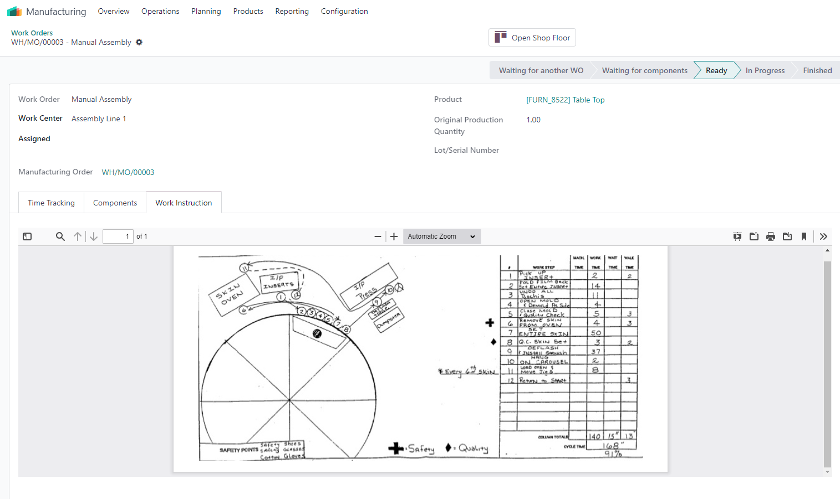

Work orders

Work orders are automatically generated and sent to each employee on the assembly line and at their respective workstations. The orders module is specifically designed for tablet screens, allowing employees to view their assigned tasks, instructions, and complete the production order directly from their screens.

Record production and components

Use barcode reading devices to accurately record the entry and exit of raw materials, materials, and finished products into production, ensuring no losses or errors occur.

Manufacturing operations

Ensure that the manufacturing instructions include visual aids, detailed projects, step-by-step procedures, and thorough quality control measures to assist the operator and minimize errors during the manufacturing process.

Advanced Features

Master production schedule

The MPS is perfect for your S&OP meeting, to align objectives of sales people and the manufacturing department.

Leverage by-products

Produce residual products by adding by-products to bills of materials.

Powerful yet simple

Although has all the features you need to deploy a modern manufacturing line, it remains very simple to use, and does not require advanced trainings for workers.

Up/down stream traceability

Track components, or manufacture in batches (lots) or serial numbers. Get a clear traceability of all operations in just a click.